1. Adult Novelty Product Manufacturing Process

Raw Material Management in Adult Novelty Manufacturing Raw material procurement and management are crucial components of adult novelty manufacturing, to ensure high-quality raw materials and secure supply for future manufacturing operations. To guarantee this supply chain security and ensure consistent product quality and supply security for future production operations. What materials are typically utilized when producing adult novelty products and how can these materials be effectively managed in warehouses?

1.1 Raw Material Procurement and Storage Management in Adult Novelty Manufacturing

(1) Major Raw Materials Used in Adult Novelty Manufacturing

Adult novelty products are produced using various raw materials, including:

Silicone: It is soft, elastic, and non-toxic, as well as having no odor.

TPE: TPE material has many advantages, including environmental protection, safety, non-toxic, tasteless, softness, and high tear resistance; the disadvantage is that it is easy to oil and dye.

PVC (Polyvinyl Chloride):For its flexibility and odorlessness, PVC plastics are widely utilized due to their relatively low prices and simple processing. PVC, however, should be handled carefully due to its toxic nature.

ABS Resin: ABS resin has long been recognized for its excellent rigidity and impact resistance making it a popular choice among structural component makers and adult novelty housings manufacturers alike.

To meet industry standards, all these raw materials must be purchased and inspected according to stringent industry requirements.

(2) Management of Raw Materials for Adult Novelty Products

Manufacturers of adult novelty products must implement an extensive system for managing raw materials, which includes:

- Storage Environment Control:

Raw material storage should maintain constant temperatures and humidity, in an environment free from moisture or dust particles.

Before being accepted in a warehouse, all raw materials must first undergo a stringent physical and chemical evaluation, meeting certain requirements before storage can occur.

- Inventory Control Mechanism

To ensure timely supply and adequate inventories, it is vital to implement mechanisms such as the scientific inventory alert system and first-in, first-out. A traceability system also plays a vital role.

Implementation of stringent record-keeping and traceability procedures must be strictly observed for each batch of raw material to facilitate post-incident investigations.

Adult novelty manufacturing demands special care in procuring and storing raw materials. Precision production relies heavily on the quality assurance of these raw materials.

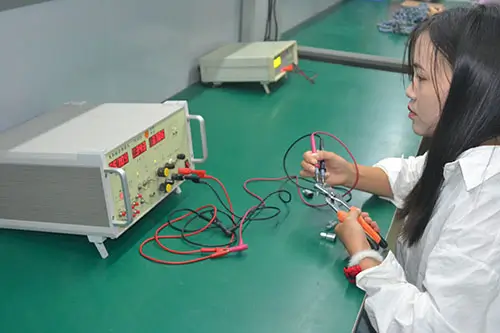

1.2 Innovative Design and Robust Construction – the Cornerstones for Adult Novelty Manufacturing

Product design and structural engineering in adult novelty manufacturing are crucial stages for its success. Each step from conceptualizing functionality and form to optimizing internal components requires meticulous planning – let’s explore its most prominent elements here.

(1) Understanding Market Needs

To develop products that resonate with consumers, design teams need a thorough knowledge of consumer insights, industry benchmarks, and emerging styles. Novelty items designed with customer-centricity in mind ensure they fulfill unmet needs while standing out among competitors.

(2) Engineered for Safety and Performance

Engineers focus their attention on optimizing the internal structure and mechanisms of their product, selecting materials, components, assembly methods, and assembly methods that optimize performance, reliability, and user security. Virtual prototyping and testing with advanced CAD/CAE software validate designs before production takes place.

(3) Aesthetics & Ergonomics

When designing Adult Novelty Products, designers should pay careful attention to both aesthetic appeal and ergonomic comfort. In balancing form with function when it comes to Adult Novelty Products design, designers carefully craft the outer shell of products paying special attention to shape, texture, and color harmony as well as internal architecture for a smooth user experience.

(4) Quality & Compliance

As part of the design and development process, stringent quality controls are in place to ensure compliance with industry standards and regulatory requirements. This involves extensive testing, documentation, and traceability systems to mitigate risk while simultaneously offering novelties of superior quality to the market.

Adult novelty manufacturers can create cutting-edge novelty products by integrating robust engineering and quality assurance processes with cutting-edge designs, captivating consumers while setting new industry standards. Such an integrative approach ensures a sustainable future in this dynamic and ever-evolving sector.

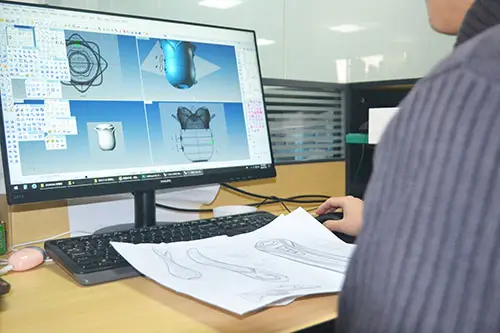

1.3 Injection Molding and Precision Mold Manufacturing- the Core Components of Adult Novelty Manufacturing

Injection molding and mold manufacturing are integral processes in the creation of adult novelty products. Every step, from designing molds to tuning molding parameters has an immediate effect on the appearance and reliability of final products. Let’s delve into their inner workings.

(1) Mold Making as the Foundation of Adult Novelty Production

Molds form the basis for adult novelty production. They determine both surface quality and dimensional accuracy for key components like product housings. To reach tight tolerances and surface finish requirements for fabrication of molds using advanced CAD/CAM technologies. Only high-precision molds can provide stability for subsequent injection-molded items.

(2) Injection Molding as the Basis of Quality Control

Injection molding is an integral step of adult novelty production, and to achieve flawless looks and precise dimensions operators must adjust various parameters such as temperature, pressure, speed, and post-processing (such as polishing or coating of parts post-production). Post-processing should also play an essential part in improving overall product quality.

(3) Comprehensive Quality Assurance Mold

Manufacturing and injection molding both demand stringent quality controls throughout their processes. Businesses should implement an in-depth quality assurance program covering raw materials, molds, injection molding, and any other critical steps. An efficient product traceability system will allow rapid root cause analysis and prompt corrective action should quality issues arise.

Mold manufacturing and injection molding are core processes in adult novelty production, both of which must be handled accurately to create high-quality adult novelty products. Precision and quality must be upheld during these two steps to remain competitive within this industry. To remain at the top, enterprises must continually improve and innovate.

1.4 Adult Novelty Manufacturing: Post-processing and Assembly of Adult Novelty Products.

Assembly and post-processing stages in adult novelty manufacturing are equally essential to its success. From appearance enhancement to precision assembly, every stage requires stringent oversight to meet product expectations. Discover more details of each process involved here.

(1) Meticulous Post-Processing Techniques

To enhance the final quality of injection molded products, various finishing processes including polishing, coating, and silk-screening may be employed post-molding to increase product quality and enhance aesthetic appeal. Polishing may help remove mold marks while coatings and silk printing provide customizable visual effects for personalized effects. To execute these specialized techniques flawlessly, professional equipment and experienced operators are necessary for the flawless execution of these specialized techniques.

(2) Rigorous Assembly

After post-processing has been completed, structural components and electronic pieces must be assembled precisely into their final products. To do this successfully requires an ideal working environment and experienced operators – any errors could have detrimental effects on the appearance, structural integrity, and functional reliability of a final product.

(3) Comprehensive Quality Assurance

For post-processing, assembly, and packaging stages a comprehensive quality management system is essential to ensure compliance with quality standards at each step; from raw material inspection through process monitoring and finished product inspection. In case of quality issues, a strong traceability system should also be put into place to quickly pinpoint their source.

Adult novel production cannot overlook its post-processing and assembly stages. To produce high-quality novelty adult products, each step in this process must be carried out precisely; to do this effectively requires continuous process improvements as well as raising quality awareness within an organization.

1.5 Secure Packaging and Efficient logistics – key Elements in the Adult Novelties Supply chain

Packaging and transportation logistics for adult novelty products cannot be neglected after production has taken place. Every step from designing internal and external packaging to planning distribution requires tight control. Gain insight into current practices employed here.

(1) Thoughtfully Designed Product Packaging

Adult novelty supply chain management places great emphasis on thoughtful product packaging design for both internal and external product shipping containers. Packaging must not only meet basic functions like anti-static and moistureproofing but should also add visual interest for customers to purchase their product(s). Recyclability, environmental friendliness, and sustainability must all be factored in to meet shifting consumer preferences.

(2) Meticulously Scheduled Logistic Distribution

A sensible logistics and transportation plan is also essential to business. Businesses should create a detailed transportation strategy that takes into account factors like product characteristics and geographical sales areas to deliver goods safely while controlling costs efficiently and keeping supply chains synchronized. A network for warehouse management and distribution should also be put in place to facilitate smooth coordination within supply chains.

(3) Comprehensive Monitoring of Quality

Packaging and distribution logistics companies should implement an in-depth quality monitoring system. This should cover every stage from raw material procurement through final delivery; so enterprises are quickly able to identify problems at their source and take corrective action quickly to ensure product quality and safety.

2. Equipment Used in Adult Novelty Manufacturing

2.1 Precision Injection Molding Machines Are Key Components in Adult Novelty Production

Injection molding is an integral component of adult novelty production, with injection molders playing an essential role in its manufacturing. Advanced machines require precise control and stable operation for accurate appearance as well as structural reliability of important parts. What kinds of injection molders are needed to produce adult novelty products?

(1) High-Precision Servo-Electric Injection Molding Machines

These high-precision injection molding machines use advanced servo technologies to accurately control parameters like temperature, pressure, and speed for flawless appearances and accurate measurements of products. Both power systems and control systems utilize this innovative servo technology for maximum precision and stability during injection molding processes.

(2) All-Electric Injection Molding Machines

All-electric injection molding machines use servomotors instead of hydraulic drives for energy efficiency and environmental sustainability, providing precise control over every aspect of the injection molding procedure that enhances both product quality and efficiency. Furthermore, this compact all-electric design provides more fluid operation.

(3) Micro-Injection Molding Machines

Micro-injection machines are an ideal way to manufacture small precision structural components at low energy consumption with reduced compactness and energy usage. Furthermore, they can produce high-precision molds as well as adult novelty items.

Summary: Injection molding equipment is an indispensable component in the production of adult novelty products. High-quality injection molders are essential tools in meeting appearance quality, structural durability, or producing differentiated goods efficiently and cost-effectively. As technology progresses, injection molding machines will continue to advance accordingly.

2.2 High-performance extruders are essential equipment in adult novelty manufacturing.

An extruder is an indispensable tool in the production of adult novelty products, from pretreatment, compounding, and other processes to stability improvement and performance indicators for final products. However, what type of extruder would best serve such production requirements?

(1) Precision Single-Screw Extruders

Single-screw extrusion machines are among the most frequently used extrusion machinery. Their advanced versions, known as single-screw advanced extruders, can precisely control parameters like temperature and pressure to ensure plastic raw materials melt and mix thoroughly during extrusion; this improves the mechanical properties, appearance, and performance of products.

(2) Twin Screw Extruders

Twin-screw extruders are ideal for composite materials that require special performance, such as products made of composites. Their superior mixing and melting abilities make for better blends between components for more effective composite creation.

(3) Micro-Extruders

Micro-extruders can also be used for small parts production in low volumes. As smaller devices with less energy usage than their large-volume counterparts, they offer high precision performance while still using fewer resources overall. They’re extremely flexible, as well; used to produce various components for adult novelty products.

Summary: Extruders are an essential component of adult novelty production. With their ability to achieve mechanical properties, product appearance, or flexible production, quality extruders play an essential role. Furthermore, technology will continue to advance as time goes on.

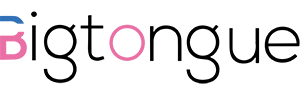

2.3 Advanced Inspection Tools – Ensuring Quality in Adult Novelty Items

Production of adult novelty products involves several steps that require strict quality control to ensure compliance, using advanced inspection equipment as part of this cycle from raw material testing through finished product tests and in-line monitoring. What equipment types are needed for manufacturing adult novelty products then?

(1) 3D Scanners

Digital models can be generated by 3D scanners that accurately measure dimensions, shapes, and other parameters. Inspecting structural components for their appearance and their dimensional consistency requires rapid inspection technology that offers rapid yet precise assessments; 3D scanners offer this benefit and improve production efficiency as a result.

(2) X-ray Inspection Equipment

The internal structure of a product can be easily tested using X-ray equipment without causing any physical damage. For instance, welding quality on electronic components or defects within plastic parts such as voids can be checked using this tool without risk to the reliability of your product. It plays an invaluable role in increasing reliability.

(3) Surface Inspection Devices

Inspection tools like optical measurement devices and microscopes can be used to inspect the appearance and surface quality of products, such as smoothness indicators for shell components or coating uniformity; aesthetic standards will only be fulfilled once this step has been accomplished.

(4) Inline Monitoring Systems

Production lines often employ inline monitoring systems to detect and record various parameters like pressure, temperature, and speed in real-time. They will notify users if anything abnormal arises that needs immediate intervention, improving both production efficiency and lowering quality risk.

Summary: Inspection equipment is key for assuring the quality of adult novelty items. Businesses can only achieve full quality control by using various inspection techniques to achieve total quality control and ensure high-quality products reach customers. Inspection technology will continue to advance over time.

2.4 Intelligent packaging equipment – an essential component in adult novelty production

Packaging adult novelty products is an integral step following production. From internal protection to aesthetic enhancement, every detail requires packaging equipment – intelligent technology has led to such equipment becoming widely used when producing adult novelty products, providing many advantages to businesses. What equipment types are needed for adult novelty production?

(1) Automated Assembly Lines

Automated assembly lines allow companies to quickly and accurately assemble products, protective material, outer packaging, and other components quickly and precisely, thus greatly increasing packaging efficiency while guaranteeing consistency and stability for every packaged product – essential elements in improving packaging quality while increasing production efficiencies.

(2) In-line Inspection Equipment on Packaging Lines

In-line inspection equipment installed on packaging lines provides real-time monitoring of quality indicators like sealing and appearance. Any abnormalities detected can be immediately stopped for adjustment if any are identified; thus helping mitigate quality risks as well as promote continuous process improvements within packaging operations.

Summary: Intelligent packaging equipment is an integral component in the creation of adult novelty products. Not only can it enhance packaging efficiency and production rates, but also streamline supply chain operations. Packaging technology will continue to advance over time.

2.5 Other Critical Support Equipment in Adult Novelty Production

Auxiliary devices are essential in adult novelty production to ensure its smooth running and quality output, though these auxiliary pieces of equipment don’t serve as primary production components themselves; nonetheless, their presence plays an invaluable role in both improving product quality and production efficiency. Let’s examine some other supporting equipment used during adult novelty manufacturing.

(1) Material Drying Equipment

Adult novelty product production often necessitates that plastic raw materials be dried before being extruded or injection molded, to remove moisture and maintain extrusion or injection molding process stability. Hot air dryers and vacuum driers can both help meet this need for various raw materials.

(2) Robotics and Automation Equipment

Automated equipment such as robotic arms, conveyor belts, and other automation devices can be used to automate product loading and unloading between processes for improved production efficiency while decreasing risk from manual operation. Integrating technologies like vision recognition or force controls further expands the intelligence and flexibility of automation equipment.

(3) Environmental Monitoring Systems

Adult novelty product production involves stringent environmental requirements in terms of temperature, humidity, and cleanliness. Production workshops should be equipped with temperature and humidification control equipment as well as clean room systems to monitor and regulate environmental conditions in real time for stable product quality production. To protect production against potential environmental problems affecting its production processes it is also wise to create an early warning system and keep an eye on environmental indicators throughout.

(4) Warehousing and Logistics Systems

Adult novelty product manufacturing processes involve storage, distribution, and packaging steps which must all be executed efficiently for production to continue uninterrupted. Intelligent warehouse management systems, logistics distribution networks, and order processing can enhance supply chain efficiency to increase supply chain productivity.

Summary: Though not essential equipment, auxiliary devices play a vital role in the manufacturing of adult novelty products. Businesses can increase their competitive edge by selecting suitable supporting equipment, optimizing it appropriately, and deploying it all cohesively. Select and optimize production equipment carefully to ensure high-quality production at efficient levels.